-

TSMC plans to build its 2nm wafer fab in Hsinchu, where land has already been obtained for the facility, according to YP Chin, senior vice president for operations at the foundry house.

Time for largest marketing hoax.

-

TSMC is working closely with a major client to accelerate its 2nm R&D and facilitate related investment procedure, the foundry disclosed at its online technology symposium on August 25.

-

TSMC started to lie

Attacking Huawei had one big reason - otherwise Apple couldn't get enough A14 LSI's made.

But new slides data and strange situation with 7nm+ process that fully disappeared from all marketing materials and slides, not good.

sa14217.jpg800 x 440 - 34K

sa14217.jpg800 x 440 - 34K

sa14218.jpg744 x 438 - 32K

sa14218.jpg744 x 438 - 32K -

Some interesting marketing lies on Intel 7nm failed process

https://bmo.qumucloud.com/view/2020-techsummit-intelcorp#/

Situation with 10nm miserable process is still staggeringly bad. And 7nm even in the early steps already proved to be worse as public delays started almost since preliminary announcement rumors.

Present industry rumors are that 7nm can be last Intel process (Similar to fake 12nm by GlobalFoundries) and delays can reach as far as 2024 as starting year for fast CPU chips.

sa14226.jpg800 x 404 - 46K

sa14226.jpg800 x 404 - 46K -

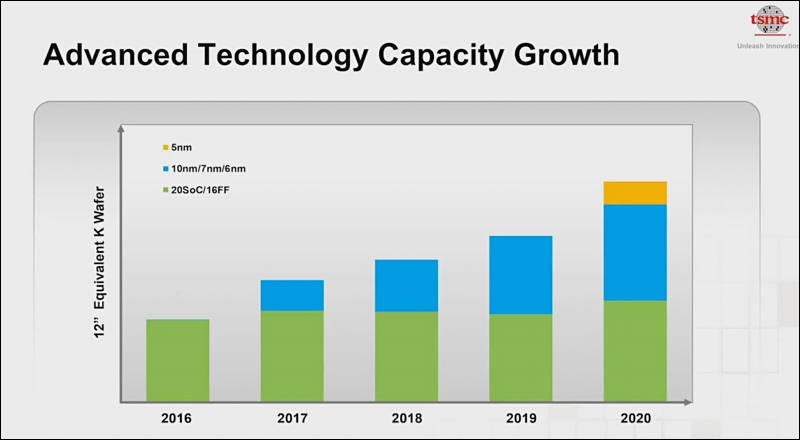

Initial TSMC plans on 5nm had been:

- Production of both Xbox and Playstation LSI already in 2020, now shifted to 2022

- Production of Huawei LSI - cancelled due to TSMC request to US

- Production of Apple A14 LSI - will be only big client using 5nm this year, but production is halved from initial numbers via delays and few other tricks

- Production of AMD Zen 3 CPUs - production shifted to 2022, may be to Zen 4 or even Zen 5

- Production of Nvidia new top GPU - production moved to Samsung factories

-

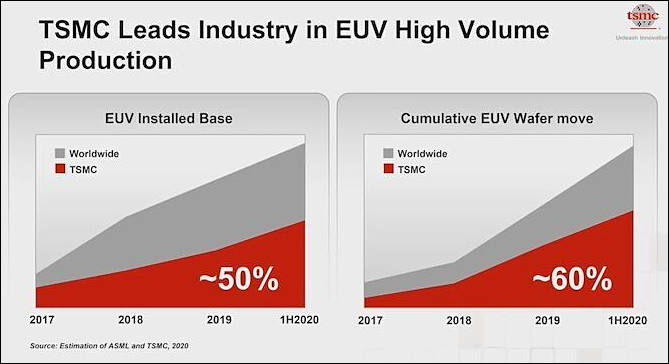

TSMC has announced that they own an amazing 50% of all EUV machine installations. It is also reported that TSMC achieves 60% of all EUV wafer capacity in the world

sa14273.jpg669 x 364 - 36K

sa14273.jpg669 x 364 - 36K -

TSMC has already scaled up its 7nm process output to 130,000 wafers monthly ahead of schedule, with the monthly production set to climb further to 140,000 units at the end of this year, according to industry sources.

Yet Nvidia had been forced to use much worse Samsung process.

-

TSMC presently has severe issues with 5nm process

Apple is gearing up for the launch of its new-generation MacBook and iPad Pro series powered by its own Arm-based processors, which will be fabricated using TSMC's 5nm process technology. TSMC is expected to start making Apple Silicon in fourth-quarter 2020.

Apple will kick off its 5nm wafer starts at TSMC for its new Apple Silicon processors starting the fourth quarter of 2020, with monthly output estimated at 5,000-6,000 wafers, according to industry sources.

Even removing Huawei upon TSMC request using sanctions and moving Nvidia to Samsung did not allow Apple to get their chips in time.

It is required to precisely track that happens with so called 5nm process (modified 7nm process with added EUV) as we have something fishy here.

-

Samsung and Nvidia 8nm issues

Presently Samsung provides multiple bins (and Nvidia charges differently for them)

- Bin-2 - chips that match initial specifications that Nvidia provided year ago, they are called elite :-)

- Bin-1 - chips requiring up to 10% more voltage and with around 15% more heat produced than specification, called normal bin by Nvidia

- Bin-0 - chips that need up to 25% more voltage and with around 20% more heat and some throttling, called as garbage bin by Nvidia, will be present in around 60% of partners cards

All top reviewers will be getting only Bin-2 chips even on cheap cards.

-

Intel 7nm problems seems to be severe

JPMorgan Chase analysts said that Intel is preparing for the new chip early. Based on this calculation, TSMC will start mass production of Intel's central processing unit (CPU) in the first half of 2022, six to twelve months earlier than expected.

Analysts said that before the mass production of Intel's 5nm chip, TSMC still has the opportunity to win Intel Xe GPU and chipset orders, using the same advanced 7nm and 6nm technologies.

-

Qualcomm Snapdragon 875 will be produced by Samsung only

Something is up with TSMC 5nm process that no one want to tell to wide public, as they literally can't even get Apple chips produced on time and sidelining all other orders, even extremely profitable.

-

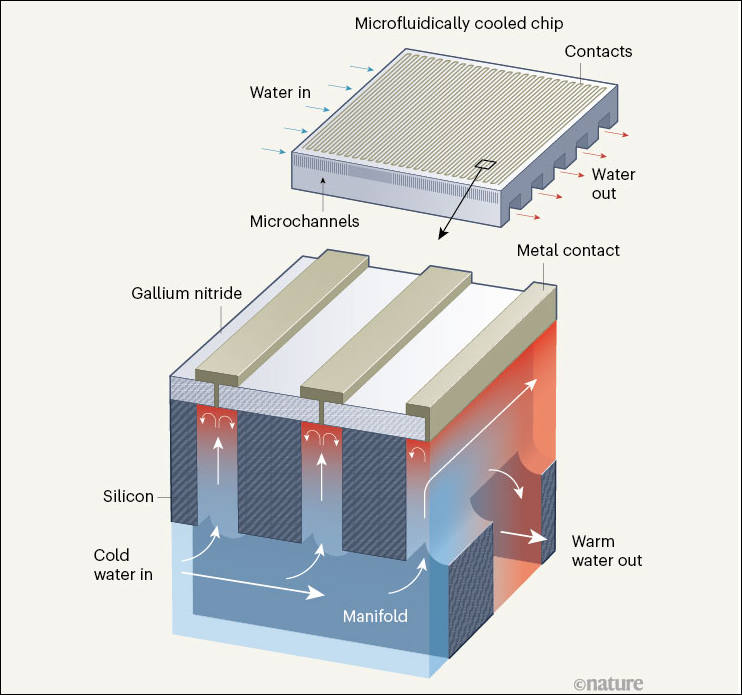

All new Apple smartphones will start to use heatpipes

Due to problems with lowering thermal performance while going to 5nm and further to 3nm (despite TSMC and Samsung claims) Apple will be forced to significantly update thermal performance of their designs.

Two solutions are expected - use of metal in the rear casing and use up to 3 heatpipes to spread the abnormal heat from central processor LSI.

Non throttling performance can drop to mere 3-4 minutes for 2021 flagmans, causing LSI to drop performance by 40-50%.

-

TSMC did not ship requested number of Kirin processors

Industry rumors are that TSMC can't produce enough chips using their 5nm process. Hence Huawei got from 1/4 to 1/3 of expected Kirin new LSI stock and can postpone any smartphones using them.

Apple also moved smartphones release dates to be able to collect enough stock of their LSI, rumor is that due to TSMC issues Apple won't be able to actually ship their new ARM notebooks in this year in any good amount.

-

Something bad is happening with TSMC last months

Sony Corp. has cut its estimated PlayStation 5 production for this fiscal year by 4 million units, down to around 11 million, following production issues with its custom-designed system-on-chip for the new console.

Company has come up against manufacturing issues, such as production yields as low as 50% for its SOC, which have cut into its ability to produce as many consoles as it wishes, said the people, who asked to remain anonymous because the deliberations aren’t public. Yields have been gradually improving but have yet to reach a stable level, they added.

Rumor is that Sony placed bet on so called 7nm+ process with EUV usage and this is reason of all issues.

As TSMC cancelled its usage in all AMD chiplets adn all other major orders and now reason is clear.

-

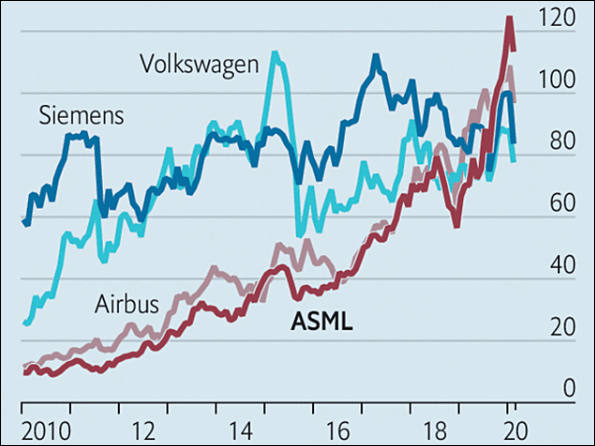

ASML

Destruction of this steppers manufacturer is very important to China at current stage as it will allow to damage western powers beyond repair.

Attack on some manufacturer stages facilities or core people is very probable and very good for overall development.

sa14603.jpg595 x 446 - 44K

sa14603.jpg595 x 446 - 44K -

If this personal attacks are true, it will be beyond repair indeed.

What strikes me is the relaxed position of USA fucking up china In the licensees but having china make them all it’s high tech stuff.

Let’s wait and see the complexes problems this party’s will have sooner than later

I feel it will be historic news.

-

TSMC's 5nm process capacity will be fully utilized through the end of 2020, thanks particularly to strong orders for Apple's new iPad Air and upcoming iPhones, as well as the Mac, according to industry sources.

Most importantly we now have proof that it was Apple who stood behind all Huawei problems.

Nice humble looking Tim Cook is the villain.

-

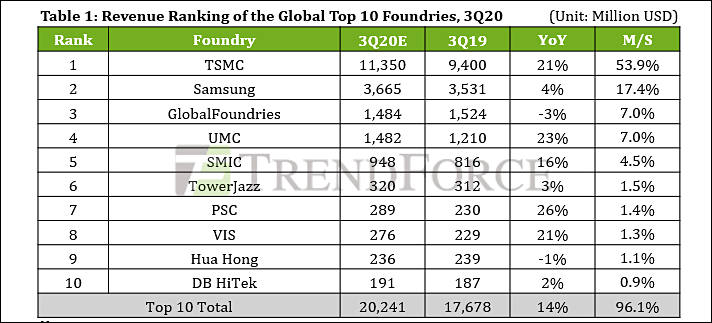

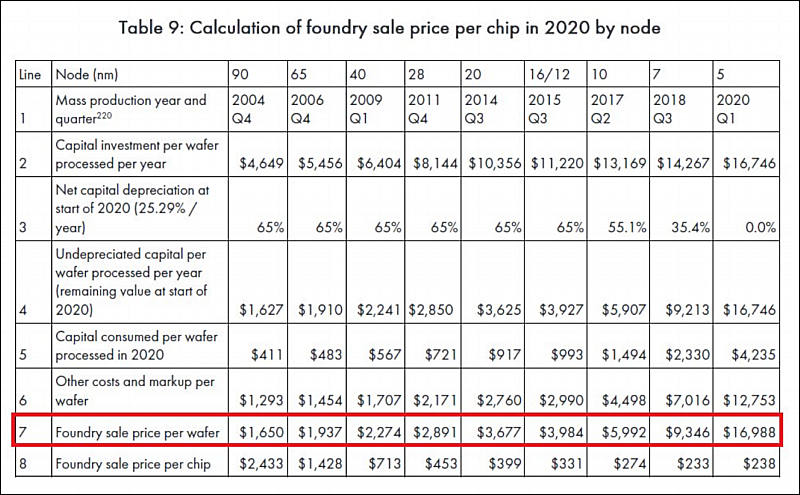

Quite weird table if do not know that it is

From https://cset.georgetown.edu/research/ai-chips-what-they-are-and-why-they-matter/

It is actually about some abstract big AI chips (610 mm2, 90.7 billion transistors at 148.2 MTr/mm2), but about real CPUs or GPUs that changes with process.

And all numbers are estimates, as making real numbers public could shock the public, so it won't be allowed no matter that.

TSMC sells a 300mm wafer processed using its N5 technology for about $16,988. By contrast, the world’s largest contract maker of semiconductors charges around $9,346 per 300mm wafer patterned using its N7 node as well as $3,984 for a 300mm wafer fabbed using its 16nm or 12nm technology.

sa14660.jpg800 x 495 - 92K

sa14660.jpg800 x 495 - 92K -

As chip makers have reached the limits of atomic-scale circuitry and the physics of electrons, Moore’s law has slowed, and some say it’s over. But a different law, potentially no less consequential for computing’s next half century, has arisen.

I call it Huang’s Law, after Nvidia Corp. chief executive and co-founder Jensen Huang. It describes how the silicon chips that power artificial intelligence more than double in performance every two years. While the increase can be attributed to both hardware and software, its steady progress makes it a unique enabler of everything from autonomous cars, trucks and ships to the face, voice and object recognition in our personal gadgets.

Between November 2012 and this May, performance of Nvidia’s chips increased 317 times for an important class of AI calculations, says Bill Dally, chief scientist and senior vice president of research at Nvidia. On average, in other words, the performance of these chips more than doubled every year, a rate of progress that makes Moore’s Law pale in comparison.

Tragedy is that energy per each performance unit is no longer dropping much.

-

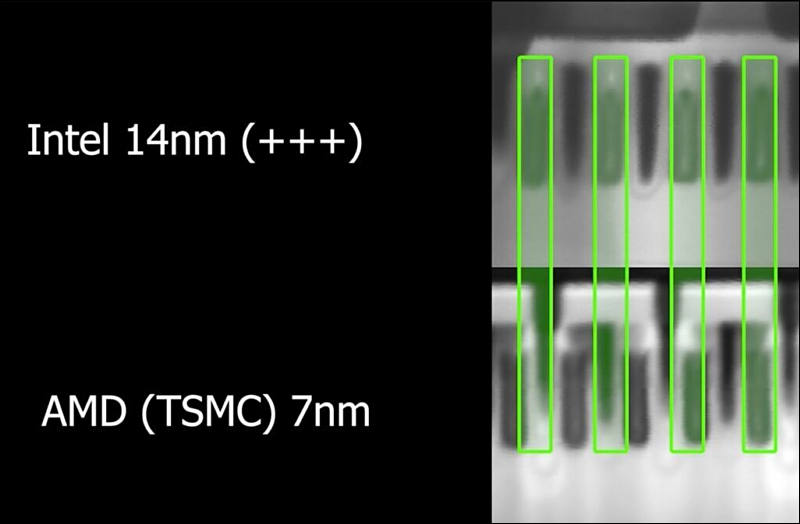

Close look at the 14nm and 7nm transistors

sa14742.jpg800 x 524 - 40K

sa14742.jpg800 x 524 - 40K -

Sony and Microsoft’s new-generation game consoles are expected to be out of stock until mid-2021. In second half availability will slowly improve.

The quantity of ordered wafers is as high as 102,000, and the recent yield rate is estimated to reach 58%, and TSMC wants to it improve significantly after the fourth quarter.

-

Taiwan President Tsai Ing-wen promised on Thursday to help the island’s key semiconductor industry overcome difficulties and consolidate its leading position, offering support to a sector increasingly caught up in China-U.S. trade tensions.

As I told - as soon as smartphone money that finances all recent developments started to dry we are going to see Japanese model - direct injection of local government money, as well as billions from US and EU freshly printed database records.

Howdy, Stranger!

It looks like you're new here. If you want to get involved, click one of these buttons!

Categories

- Topics List23,990

- Blog5,725

- General and News1,353

- Hacks and Patches1,153

- ↳ Top Settings33

- ↳ Beginners256

- ↳ Archives402

- ↳ Hacks News and Development56

- Cameras2,366

- ↳ Panasonic995

- ↳ Canon118

- ↳ Sony156

- ↳ Nikon96

- ↳ Pentax and Samsung70

- ↳ Olympus and Fujifilm100

- ↳ Compacts and Camcorders300

- ↳ Smartphones for video97

- ↳ Pro Video Cameras191

- ↳ BlackMagic and other raw cameras116

- Skill1,960

- ↳ Business and distribution66

- ↳ Preparation, scripts and legal38

- ↳ Art149

- ↳ Import, Convert, Exporting291

- ↳ Editors191

- ↳ Effects and stunts115

- ↳ Color grading197

- ↳ Sound and Music280

- ↳ Lighting96

- ↳ Software and storage tips266

- Gear5,420

- ↳ Filters, Adapters, Matte boxes344

- ↳ Lenses1,582

- ↳ Follow focus and gears93

- ↳ Sound499

- ↳ Lighting gear314

- ↳ Camera movement230

- ↳ Gimbals and copters302

- ↳ Rigs and related stuff273

- ↳ Power solutions83

- ↳ Monitors and viewfinders340

- ↳ Tripods and fluid heads139

- ↳ Storage286

- ↳ Computers and studio gear560

- ↳ VR and 3D248

- Showcase1,859

- Marketplace2,834

- Offtopic1,320