-

Want to get some hints that corporation and banks own the world?

It is really simple. Look how effective they prevent goverments on imposing restrictions on their actions.

Of course, few pretty puppies make some noise on TV from time to time.

But I do not see this noises have any real effect.In fact, proper system must impose big regulations and certain standards on mass produced goods.

- You must not be allowed to use custom batteries, protected chipped batteries

- Same for chargers

- Fixed build in batteries must not be allowed in any products indended for general public

Same goes for printer cartridges

Every corporation must have obligation to produce part for 10 years, they must be available for purchase via special site all this time, and total price of all parts must be no more than original product price

- If expected life of the product is 10 years or more, this time goes up to 25 years.

Every product must contain full schematics and full assemble and disassembly instructions. Products without this are not allowed to be sold.

Special tax must apply for the goods that have many similar parts with previous model, but prevent people to upgrade their old model buy purchasing this parts due to some incompatibility. Tax must be around 200% of MSRP.

Look at the tablets and smartphones. Perfect dream for corporations.

Short release cycle, big repair costs, big prices for replacement parts, fixed batteries in most models, frequently fixed ram and flash amount, special software design to prevent or make hard upgrades or full access to device, special restricted software markets.

Generally all this shit is quite simple. Every such thing consist from main board, sometimes wifi board, speakers and microphones, cameras, battery, screen and case. Having proper standards and proper system it can be ideal modular platforms. Most do not want to change case (except for one that allow bigger battery, may be) wi-fi or speaker, many are ok with old screens, many just want to change build in flash or add ram, may be just upgrade whole MB.

Look at the PC world. One big corporation made error (in their self interest terms), as they made modular system. I personally knew the cases from 286 computers that perfectly worked with MB two generations after that, and 386SX cases that ended life with Pentium II (due to ATX standard, otherwise they ahd been ok).

-

Yes - and it doesn't make ecological sense either, that things can't be repaired or upgraded easily.

-

I'll tell you even more fun story.

Get any air purifier (with various filters, etc).

After this try to replace filters, usual price for them is astonishing (for some brands it is equal to new purifier total price)

Same thing goes in many many areas.

-

Like bloody Ink toner. I'm sick of buying a new printer every 6 months!

-

You just need to understand that in current system all measures that you see in my post are impossible to implement.

-

I understand the battery chipping issue as I design Li-ion battery packs on occasion. As we all know, Li-ion packs are very sensitive to charge/discharge rates, temperatures, voltages, etc. If any of these get out of line for the cells, then FIRE. To design a pack means you have to keep the consumer from trying to connect their pack to something not designed to be used with it. Sometimes that means trying to "charge" the pack with crazy things and sometimes that means trying to connect it to a device that is going to cause the pack to become hazardous. This is a safety thing and you HAVE to do it. That is why the "smart battery system" or SMS was created, so that Li-ion packs of significant hazardous size are inherently safe by incorporating an ACTIVE protection system within them comprising the "gasgauge" controller which monitors the charge/discharge rates, voltages, temps, etc. If this chip detects any problems, it signals the "smart charger" (which handshakes with the battery to determine it's charge rates and so forth) and/or device to shut off FOR SAFETY. This is why these batteries are "chipped", not any other reason. If a "chipped" battery doesn't work with a device, then it's because the battery has decided that it is UNSAFE to be used with that system due to one or more of it's criteria being out of working spec. This is also why the cases to the battery packs are different, so that people don't try stuffing them into all kinds of different places that they are not designed to work. Also, If a Li-ion battery does NOT have a chip, as most of the chinese copies do not, then you are forewarned that it's dangerous and could cause a fire, and lithium fires are very hard to put out. I should know, I've tried to put one out.

-

Thing is that it must be standards for all this, and under unacceptable chipped batteries I mean proprietary chips. No one prevent you to use chips helping with charge and indentification that are made according to standard.

-

@svart: I strongly disagree with your arguments regarding "chipping" for a number of reasons:

There is no significant consumer benefit to use battery packs in comparison to the usage of individual cells. The chemistry of individiual LiIon and LiPoly cells is pretty simple, the complexity of a charging circuit for them is even simpler than that required for NiMH or NiCD cells - it just takes a constant current source that is also limited to never provide more than one accurately defined voltage. To provide against under-voltage or over-currents while discharging, a simple protection circuit per cell is advisable that is so small and cheap that most standard LiPoly cells (like the 18650s), sold to consumers at a few bucks each, can already contain them (ruling out fires due to short-circuiting when mis-handled). By using individual cells - as usual with most NiMH or primary cells - there is also no need to throw away a complete battery pack if just one individual cell fails. And those cells could be bought everywhere, could be used in many kinds of devices - we've had all of this with the primary cells before, and it was very good.

If "chipping" was actually done to protect consumers from hazards, there would be no reason to not use a standardized protection circuit. But it isn't. Chipping is only done to protect profit margins of battery pack producers - while the actual quality of the security measures implemented in consumer electronics is pretty bad.

Also, if the consumers security was the motivation for chipping, the manufacturers would probably sell the original batteries at reasonable prices, not at 5 to 10 times the price of a 3rd-party battery. Even the most elaborate protection circuit would certainly not increase the manufacturing cost of a battery by more than 20%.

@Vitaliy_Kiselev: I agree with most of your points in the initial posting, but one is certainly over the top: "total price of all parts must be no more than original product price" - it is obviously expensive to sustain a stash of spare parts, and being required to sell them individually makes logistics and storage even more expensive. Let's say the "sum of all spare parts must not exceed 3 times the original price" - that would be more realistic.

BTW: When I was young, it was absolutely common to get a schematic within the instruction manual for consumer goods. Even television sets or computers came with large schematics that named every single resistor. It is a crying shame how the prevention of fixing goods has become part of common business models.

-

I agree with most of your points in the initial posting, but one is certainly over the top: "total price of all parts must be no more than original product price" - it is obviously expensive to sustain a stash of spare parts, and being required to sell them individually makes logistics and storage even more expensive. Let's say the "sum of all spare parts must not exceed 3 times the original price" - that would be more realistic

It is not. Main goal for this is to make it very hard to make big sudden changes, as each such change requires to keep producing old spare parts with new parts.

-

That's why modern Nikon lenses have printed number "10" in the recycling sign. It should mean they won't last longer than 10 years. It is not true, as professional lenses by Nikon are done to last much much longer, but the company has no obligation of producing spare parts for another 25 years. It is up to their good (or bad) will.

-

@Vitaliy_Kiselev I love that Fixer's Manifesto. And it seems to be about taking an active part, or if you have to "consume", then buying things that can be upgraded, and taking an active part to improve what you consume.

-

Hmm.

One issue is that if you have credits available and do not use them, you are usually at disadvantage to competition.

Same with consumer economy. As fixing industry is almost non existent, by going this route you reduce division of labor complexity. Hence, become less competitive.

-

@Vitaliy_Kiselev There is a standard for this, it's called the SBS or Smart Battery System. http://en.wikipedia.org/wiki/Smart_battery_system

@Karl I don't know why you think this way but you are unfortunately very wrong. Maybe you are thinking of Lithium batteries, like what watches and hearing aids use? These are NOT the same design as Li-Ion. I understand your thought process but you are not understanding the fundamental chemistry difference between Li-Ion/Li-poly and NiMH/Nicad and apparently do not understand how Smart Batteries work and why they are designed as they are. NiMH and NiCd are not a FIRE danger when datasheet discharge/charge rates are violated while Li-ion are a danger and Li-poly are less of a danger but still a danger none-the-less. Very specific charge/discharge rates of these Li-ion cells would prevent single removable cells because you would not be able to monitor each cell as is done currently in SBS packs. This doesn't even take into account the proper way to charge a Li-based cell to maintain it's useful lifetime. Without the proper charge regulation your Li-ion cell's lifetime will be 1/2 of what it should have been. The charge cycle is 2 or 3 stages for Li-Ion. This is done in conjunction with the "smart charger" through communication on the SMBUS (similar to I2C but with specific battery related communication) to regulate the current AND voltage.

Stage 1: Constant Current. The charger monitors the current to the cells via the GasGauge IC that's inside the battery pack.

Stage 2: Balance. Each cell MUST have the same charge or else you'll have cells that discharge more heavily than others and will either wear out or burst and FIRE.

Stage 3: Constant Voltage. This initiates around 75% charge and then tops the cell off. You could do CV charging only but it would take a long time to charge.Li-ion batteries are not any more simple than NiMH or NiCad. Actually, SBS systems can accurately charge NiMH and NiCad batteries as well, provided they have some feedback from the cell or pack in the form of charge rate, voltage and current.

-

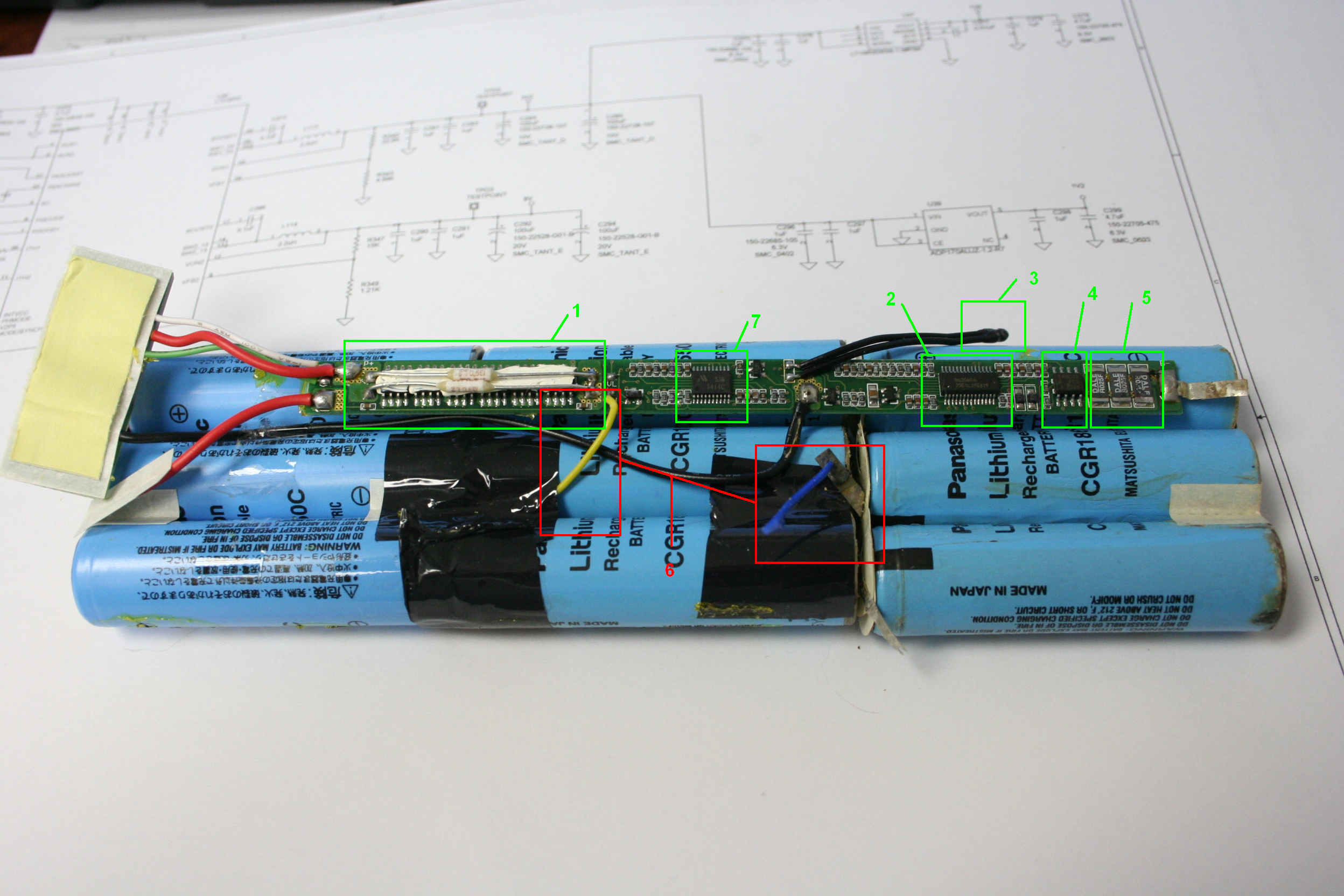

So, I've taken the liberty of documenting a picture of the inside of a Li-Ion pack that I designed.

1: Thermal fuses and MOSFETs for cutoff. These cut off the power in/out of the cell in case of excessive charge/discharge/temperature.

2: GasGauge IC: This communicates with the charger and monitors the charge/discharge/temp/currents/voltages, etc, to make sure the pack is healthy.

3: Thermistor: This is how the gasgauge checks temperature.

4: EEprom: Stores the manufacturer battery settings for charge/discharge rates, etc.

5: Current sensing resistor array: Low ohm resistors across which the current is measured.

6: Current/charge/balance sensing: these wires sense loads and balance between cell banks to make sure that each cell is balanced to the others to ensure none of them are charged or discharged differently.

7: Specific protection IC: This IC is what controls the MOSFETs. This IC communicates to the gasgauge IC and also listens on the SMBUS for warning flags from the charging IC in case the pack needs to be disconnected for safety.As you see, these packs are NOT simple and there is a LOT going on inside of them that you are not aware of. These protection devices are NECESSARY and are not there for making profits. If you want someone who makes profits, look at the chinese making the Li-Ion packs that do NOT have the protection installed and wait for them to fail and/or cause fire. Those packs are for profit because they WILL fail and cause a fire and those guys don't give two shits if they do or not.

battery.PNG2496 x 1664 - 7M

battery.PNG2496 x 1664 - 7M -

And why not have all this build into notebook and allow people to insert individual cells (with independent cell charging ability)?

-

Some of the smaller single celled devices and Li-poly are starting to do that because they can monitor single cells much easier. Multi-celled systems still need cell balance monitoring (monitoring each bank of cells) and it's just easier to do that inside the pack itself. I expect that as Li-Poly becomes more mainstream and the newer, safer, battery chemistries start to come out, it will happen. Some of the new small "rechargable" Lithium batteries available in common sizes, AA, AAA, etc, have special protection built into them which makes them usable without monitored protection, but they have limits on current density and size. The larger, high-density, cells still need monitored protection.

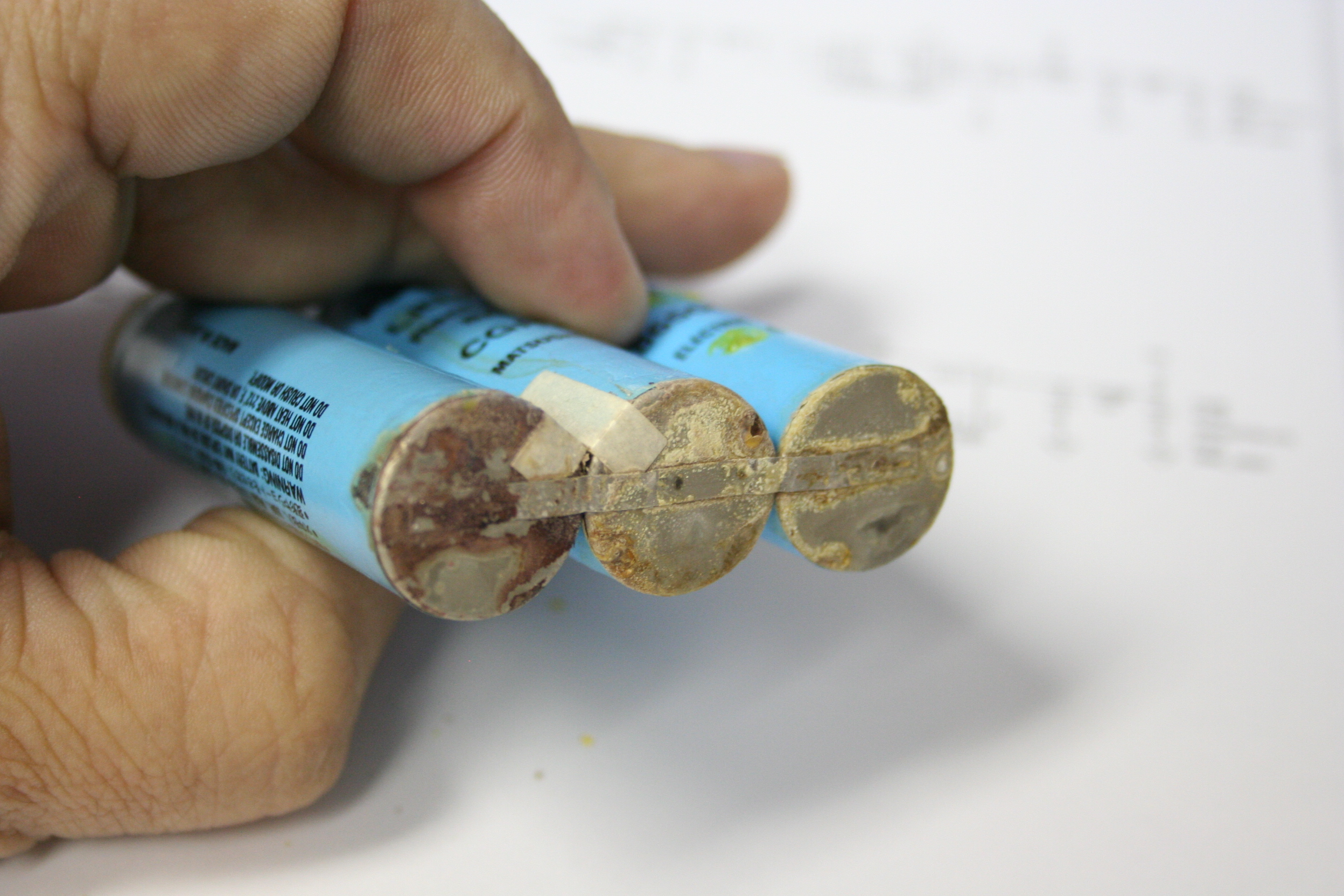

This is what happens when a Li-Ion battery is charged/discharged or simply left without a charge for too long:

The cells will spontaneously corrode from the inside and can catch fire as the lithium gel reaches the air/moisture. Luckily, these have some chemical suppression to keep that from happening but can still happen if it gets bad enough to reach the inner layers.

corrosion.PNG2496 x 1664 - 7M

corrosion.PNG2496 x 1664 - 7M -

@svart: The different approaches to load LiIon/LiPoly cells vs. NiCd/NiMH are not news to me. But once you use (individually) protected LiPoly cells connected in series, not organized in "banks", there is no balancing stage required (yes, the least capabale of the cells will then determine the point at which further discharging is prevented by the protection circuit), and since one of the major contributors to prolong the lifetime of a LiPoly cell is to best keep it between ~15% and ~85% charge all the time, it may be a good idea to stop discharging earlier, anyway, and to not necessarily exploit the capacity only reachable by the final CV loading stage.

And regarding cameras, we are talking about usually not more than 2 (sometimes 3) cells, so it would not be difficult to house individually controlled, user exchangeable cells.

Regarding...

The cells will spontaneously corrode from the inside and can catch fire as the lithium gel reaches the air/moisture.... have a look at "SECTION 19: Battery Disposal Instructions" at page 10 of this safety data sheet. Interesting advise, given the danger of catching fire you mention.

Regarding...

... or simply left without a charge for too long... isn't it then very dangerous how LiPoly cells are glued into consumer devices that are almost sure to be left unused in some drawer for a very long time, somewhen throughout their existence? We all know the advices regarding primary cells - to remove them whenever a device is not used for a longer time. But there is no such advice - and with glued-in batteries no such possibility - to do that with most LiPoly batteries.

Last but not least, the only LiPoly battery that "ballooned" on me was an original, chipped Sanyo battery charged in an original Sanyo loader. And the only person I personally know who actually experienced a Lithium battery catching fire was the owner of a MacBook, with built-in original batteries. And the large scale product call backs we saw from various notebook manufacturers were not because of any charging/discharging issue or 3rd-party parts, but because brand manufacturers delivered poor quality cells destined for cell-internal short-circuits.

-

Just because you can place a polymer underwater to deactivate it, doesn't mean that a battery that has been abused and the elemental lithium has precipitated out of the ionic gel won't catch fire.. Because it will. The key is that the lithium in a polymer is not the same reactivity as elemental lithium, especially the newer chemistries, as you attempted to use as an umbrella justification. These manufacturers are trying very hard to make a much safer lithium battery, not just for our good, but so they don't have lawsuits if one catches fire. Also, as lithium metal is highly reactive, once placed in water, you'll get this reaction: 2Li+2H2O=LiOH+H2. Yes, H2 is hydrogen gas, which is highly flammable. Think Hindenburg..

Anyway, the explanation to the salt water is that salting the water for the Li-Po battery is creating a medium power discharge path through the electrolysis of the water and the water itself is conducting heat away from the pack so that the cells don't go into thermal runaway. It's nothing more than that. No magic, no special properties of Li-po packs. Nothing. Unlike Li-ion cells, Li-Po packs are made from layers of plastic, foil and wire and are WATERPROOF unless scratched.. Then the same rules apply as Li-ion.

Anyway the same industry rules apply for Li-PO as Li-ion as far as safety regulations are concerned though. All else is just agenda and propaganda.

While gluing Li-po packs into devices is technically dangerous, they STILL have active monitoring and active protection systems involved. These protection systems are designed to cut the battery off if it gets too low in charge. Li-Ion and Li-PO have very low self-discharge rates unlike NiMh. Some of these Li cells can sit for years or decades before self discharging. The protection circuits are setup for being dead-man switches. Once they have tripped and turned off they do not use power from the cells, you need to give them a "wake up" current for the gasgauges to reinitialize and test the internal cells. The manufacturer simply expects you to use the device until the battery has lived it's life and you are expected to recycle it. In either case, unfortunately, the manufacturer is not liable for any disposal and doesn't typically care what happens. The industry has typically downplayed the safety hazards of Li-based batteries. There have been hundreds if not thousands of cases where batteries in laptops, phones, toys, etc have burned people or burned down buildings. They've burned up planes, hangars, cars, boats, etc, too. Trust me. I've been around folks who designed packs that burned down houses and stuff.. It's a legal nightmare.

And as you pointed out, the manufacturers didn't have recalls due to protection circuit problems, they got faulty cells. You will rarely see protection circuit faults because these are VERY heavily invested in. Manufacturers know that they are on the hook if a battery catches fire and burns someone. That's a big-time lawsuit waiting to happen. They will skimp on features but not on protection. If they do, then they shouldn't be in business. All the circuit protection in the world won't protect against faulty cells unfortunately. However, this won't stop manufacturers from designing protection circuits and making specific batteries so that people can't use batteries in improper places.

Overcharging a LI-po battery:

:)

Oh, and just for giggles, this random internet spec sheet(similar to the one you provided) says nothing about water submersion.. http://www.4-max.co.uk/pdf/dos-and-donts-lipo.pdf

-

@svart: Regarding hydrogen: You can find the same danger described for NiMH batteries:

Battery may emit electrolyte or hydrogen gas if charging or discharging rates exceed manufacturer’s recommendations or if pack has been breached.We certainly agree that all kinds of batteries need to be protected against certain kinds of mis-handling, we just disagree on whether that justifies manufacturers to dongle their devices against usage with 3rd-party batteries, and whether the protection mechanisms explains a 5 to 10 times factor in the price of "original" vs. "3rd-party" batteries.

-

@karl I don't think we disagree that safety is most important. I think what I disagree with is the implied notion that manufacturers actively and maliciously "chip" their batteries so they don't work. Of all the designs I've done across a handful of companies and of all the designs I've seen from other companies, I've not once seen a Li-ion assembly that had any kind of actual denial systems built into their electronics. I've disassembled all kinds of batteries from various laptops, consumer devices, and so forth, both for personal learning and for competitive analysis :) and have not once seen anything out of the ordinary. Battery shape may inhibit the use of battery assemblies in other devices, like the Gh1/Gh2 battery differences, but in all of the cases I've investigated there was some outstanding difference in the battery design that necessitated denying the end user from being able to generically use batteries in other devices. Most people only see similar power ratings and generic battery chemistry and then generically assume that it should work the same, but they don't know enough to know that sometimes the numbers and buzzwords they see aren't the whole story. I'll say that there are probably a few manufacturers that DO change mechanicals just to keep folks from reusing the same batteries but I'll stand behind my claim that MOST do not. Occam's Razor dictates that in this case, the manufacturer probably just needed to change for form, fit or function, or to simply fix a design issue rather than actively trying to screw a customer. The problem with this idea is that customers are fickle and they tend to get bent out of shape over the small details rather than the large issues, and in cases where they are required to spend a large chunk of money on a seemingly simple (and therefor cheap) device, like a battery, the company absolutely knows that they might lose business once a customer is outraged over the price. The problem lies with people like the Chinese who supply a dangerous but cheap product that seemingly comes at the right price point to uneducated consumers but unfortunately also has the side effect of reinforcing the idea that the cheap price is fair, even though it's not even close to being the same quality of product. This forum had a large number of complaints of folks buying the chinese batteries and using them once. Then they no longer worked. Of those that did work, many complained of erratic charge and life times and of course, no battery charge indicator on the camera. I bought a pair of them and disassembled one. No protection was offered at all and of course, no GasGauge IC, so no battery charge indicator either. The one battery I disassembled soon ballooned up so I recycled it. The other didn't even work out of the box so it got recycled too. I ended up using the little plastic cases for DC inputs into the camera so I could power it externally. So 25$ down the drain just for a little plastic case and I ended up buying a 60$ spare GH2 battery anyway.

-

It looks like corporations do not really like modularity at all

http://semiaccurate.com/2012/11/26/intel-kills-off-the-desktop-pcs-go-with-it/

-

Interesting news. It follows the consumer trend though. More people buy phones, tablets and laptops than desktops by far these days. I don't know the real numbers but based on the buying trends over the last few years, I read that it would only be a couple more years before the generic consumer stopped buying PCs altogether. I'm not sure this will proceed as planned though, I bet there will be a big push back against Intel and they'll at least keep a few options open. In any case, the last few generations of CPU from all of the manufacturers have essentially been un-balled BGA packages anyway. I think they can keep the option for balling up to the buyer and a new pressure socket will emerge. I've used testing sockets with little pins that match BGA balls so you can use a chip without actually mounting it. I've also hand soldered BGAs a few times, so I'm not too worried if I need to change it out.. :)

Howdy, Stranger!

It looks like you're new here. If you want to get involved, click one of these buttons!

Categories

- Topics List24,090

- Blog5,725

- General and News1,399

- Hacks and Patches1,153

- ↳ Top Settings33

- ↳ Beginners256

- ↳ Archives402

- ↳ Hacks News and Development56

- Cameras2,397

- ↳ Panasonic995

- ↳ Canon118

- ↳ Sony156

- ↳ Nikon96

- ↳ Pentax and Samsung70

- ↳ Olympus and Fujifilm102

- ↳ Compacts and Camcorders300

- ↳ Smartphones for video97

- ↳ Pro Video Cameras191

- ↳ BlackMagic and other raw cameras145

- Skill1,960

- ↳ Business and distribution66

- ↳ Preparation, scripts and legal38

- ↳ Art149

- ↳ Import, Convert, Exporting291

- ↳ Editors191

- ↳ Effects and stunts115

- ↳ Color grading197

- ↳ Sound and Music280

- ↳ Lighting96

- ↳ Software and storage tips266

- Gear5,420

- ↳ Filters, Adapters, Matte boxes344

- ↳ Lenses1,582

- ↳ Follow focus and gears93

- ↳ Sound499

- ↳ Lighting gear314

- ↳ Camera movement230

- ↳ Gimbals and copters302

- ↳ Rigs and related stuff273

- ↳ Power solutions83

- ↳ Monitors and viewfinders340

- ↳ Tripods and fluid heads139

- ↳ Storage286

- ↳ Computers and studio gear560

- ↳ VR and 3D248

- Showcase1,859

- Marketplace2,834

- Offtopic1,343

Tags in Topic

- idiots 102