-

Nice example - thick coconut fiber on top of lot of small individual springs. People who make this usually had severe issues in physics at school.

Most modern mattresses are made by managers and marketing geniuses.

Usually "orthopedic" word means that mattress will damage your spine in some especially sadistic unique way.

Same goes to bed itself - orthopedic ones usually cause most damage to costly mattresses and to your spine.

Always remember - the less uncontrollable shit you have in system - the better.

-

https://www.youtube.com/channel/UCkeJWPgqmVGDgVou5YBPmZA

https://johnryanbydesign.co.uk/understanding-beds/

Recommend to read and watch this guys

-

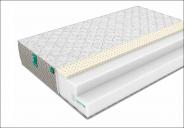

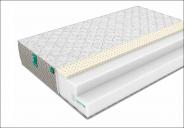

Common issue - putting some cheap memory foam above latex layer. Memory foam can be extremely non breathable in the compression areas (hence all this pillows with gel), and on mattress it can be useless waste of money. But can be also solution for comfort and support issues.

Also note that all "natural latex" will be 20% natural/80% synthetic mix (say thanks to EU bureaucrats).

Yes, and 100% natural will be 92-96% (all else is required to make it last).

sa16087.jpg791 x 412 - 45K

sa16087.jpg791 x 412 - 45K -

The zero-metal content of latex mattresses make them very popular among those who want to sleep safely. In contrast, the metal springs in spring coil mattresses are believed to amplify electromagnetic radiation, acting like an antenna: this is not a good environment for our bodies to sleep on.

This is really shitty marketing.

-

Example of proper distance between planks (normally you never see such on all but some premium beds)

Cheaper variant of adjustable center planks and proper distance between plans

Adjustable bases

sa16104.jpg800 x 485 - 69K

sa16104.jpg800 x 485 - 69K

sa16152.jpg800 x 461 - 74K

sa16152.jpg800 x 461 - 74K -

Unfair sales tactics are being used to make customers pay thousands of dollars more than they need to for a mattress. A CHOICE investigation has found manufacturers work with retailers to make buying a mattress confusing, even anti-competitive, by using practices designed to take bargaining power away from shoppers to fatten their profit margins. The industry – secretive, controlled and organised, as our investigation shows – is not unlike a cartel.

-

What "hard" actually means?

If you go around you will find such thing in the description of every mattresses

- very hard

- hard

- medium

- medium-soft

- soft

- very soft

And similar.

In reality it is usually pointless creation of marketing teams, instead of real properties you need to know.

First property is how much mattress will compress if you put same size piece of plywood on it and load with specific weight.

Normally you can guess this from "maximal human weigh" or "maximum load" number in specification, so weak springs or cheap foam will have 90-115kg rating, medium quality go from 125 to 145kg and strong go from 150 to 300kg.

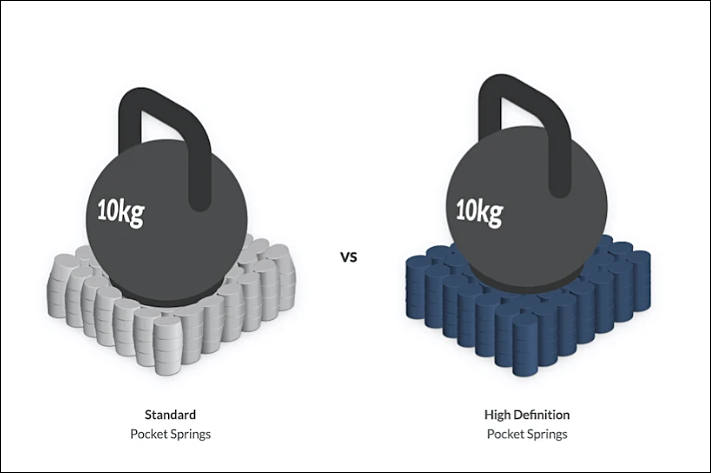

Second property is how much it will compress under concentrated weight.

This depends on mattress construction as much as from how strong a foam or springs are.

For example, mattress with small amount of strong springs will feel "hard" or close to it. As it will both compress not much under even load, but it will also compress not very much under concentrated load (due to weight distribution).

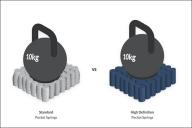

Usually all cheap mattress manufacturers like to put some kind of weight distribution layer, like coconut fiber. Such way you can use weaker and lower quality springs or cheaper foam under it. As weight will be distributed by firm layer. Lot of this guys also state that it is good for ya.

Expensive mattress with lot of small springs behave differently. Due to springs number it still won't compress much under even distribution. But with concentrated load it uses only small amount of individually quite weak springs, so it compresses much more. Hence the term "soft" or even "very soft is used".

Here the better is top layer - the more soft and contoured it will fee like. Usually 3-5cm latex and small protection layer (that protect latex from springs pressure and distribute it, but not wide) are enough.

Issue here is that capitalist manufacturers don't like this, so they try to put as much stuff as possible on top. As it allows to charge more money, despite making little sense from physics standpoint.

Btw, look for mattress with different hardness, as they advertise this. But not to sleep on other side (you can experiment, but feeling will be very different). As having 3cm coconut or such on the bottom side is very nice for your springs. Such layer will distribute load to your bed base evenly.

sa16139.jpg711 x 473 - 26K

sa16139.jpg711 x 473 - 26K -

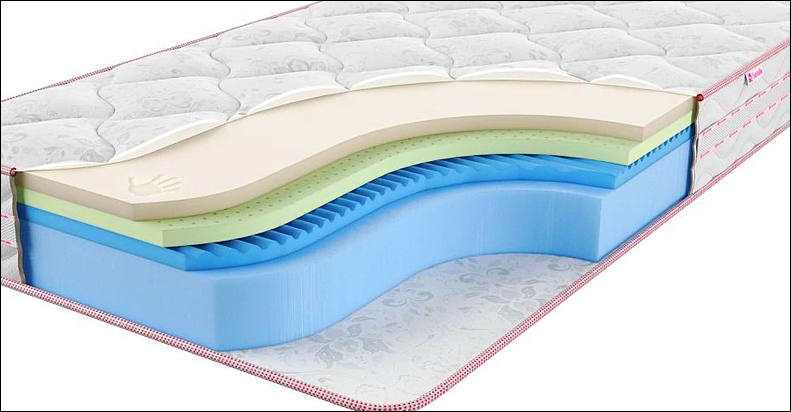

Capitalists tricks with foam mattresses

Suppose you look at such cheap mattress. Where is the catch?

First, top natural latex layer will be at best 20/80% blend (20% of real thing). And at worst it will be colored 1%.

It is important, as cost of 100% natural latex is at least 3.5-4x times more.

Next - basic thick foam layer will be firm form of low density. Here factory cost depends only on the density and nothing more. This is why cheap mattress weight can be 2 or 3 times less compared to good one (or even more sometimes). Btw with latex layer they do the same.

In other words - capitalist try to sell you empty air for your real money.

sa16142.jpg800 x 557 - 46K

sa16142.jpg800 x 557 - 46K -

Octasprings - abnormal marketers idea

In avia seats it is very useful (for companies) to save weight, but not in any mattress where it goes directly back, making comfort and durability worse than good metal springs. Looks nice but besides making things worse and allowing manufacturer to save (as weight will be less, so less material) it is useless.

-

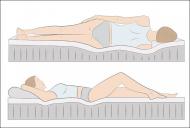

If you see any foam with uneven surface you must know what it is not made for "air circulation" or "micro massage effect" as advertised.

The only reason is to be able to advertise and show taller mattress while paying less for foam, as any contoured foam will cost at the factory based on how much actual foam it has.

For your body it is bad and it is also bad for life of top layers as such cheating create uneven force distribution.

sa16150.jpg748 x 432 - 32K

sa16150.jpg748 x 432 - 32K -

Smart way to make mattress cheaper for you

First - if you have slatted base - get mattress with 2cm or more of coconut fiber at the bottom, this evens out the load.

Second - get the square mattress (usually 200x200 or more) if you have space for it. As it allows you to turn it by more ways and it wears evently.

sa16214.jpg800 x 550 - 53K

sa16214.jpg800 x 550 - 53K -

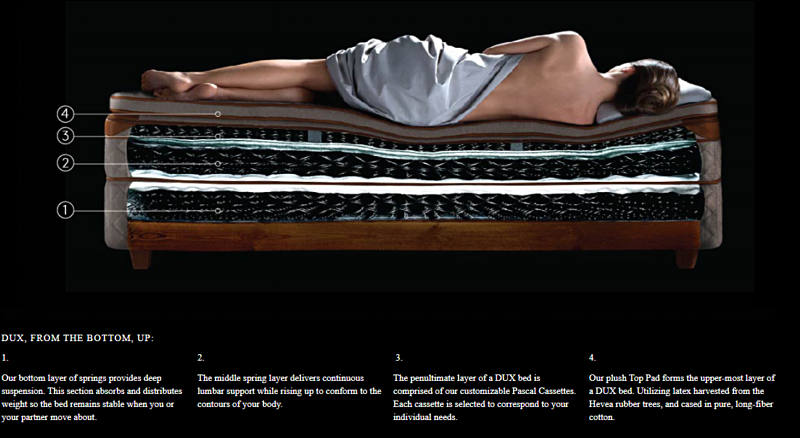

Ideal mattress (one you will buy in 95% cases won't be such)

sa16343.jpg677 x 456 - 35K

sa16343.jpg677 x 456 - 35K -

Latex manufacturing

This guys make around 90-95% of all mattress usage latex in Mordor, all of it is 20% natural/80% domestic oil based

sa16375.jpg800 x 597 - 64K

sa16375.jpg800 x 597 - 64K

sa16376.jpg800 x 596 - 69K

sa16376.jpg800 x 596 - 69K

sa16377.jpg800 x 526 - 58K

sa16377.jpg800 x 526 - 58K -

On fancy mattress covers

From talk with leading manufacturing manager:

On our mattresses, the fabric goes for 250 g of holcon, which is a 2 cm layer.

And why such thick mattress covers? Perhaps a thin, durable elastic case is better.

Competition, due to the appearance, although the consumer value in a normal mattress filling is zero.

From me - actually it is not zero, it is negative.

sa16345.jpg800 x 529 - 55K

sa16345.jpg800 x 529 - 55K -

Coconut coir manufacturing

sa16371.jpg800 x 580 - 105K

sa16371.jpg800 x 580 - 105K

sa16372.jpg800 x 597 - 74K

sa16372.jpg800 x 597 - 74K

sa16373.jpg800 x 594 - 119K

sa16373.jpg800 x 594 - 119K

sa16374.jpg800 x 595 - 139K

sa16374.jpg800 x 595 - 139K -

There are 5 main components or "specs" that determine how layers perform and interact in a mattress and several smaller components to the pressure relief / alignment "equation". Before I get started ... for those who are looking for more "simple" information ... this post may be a little on the long or technical side !

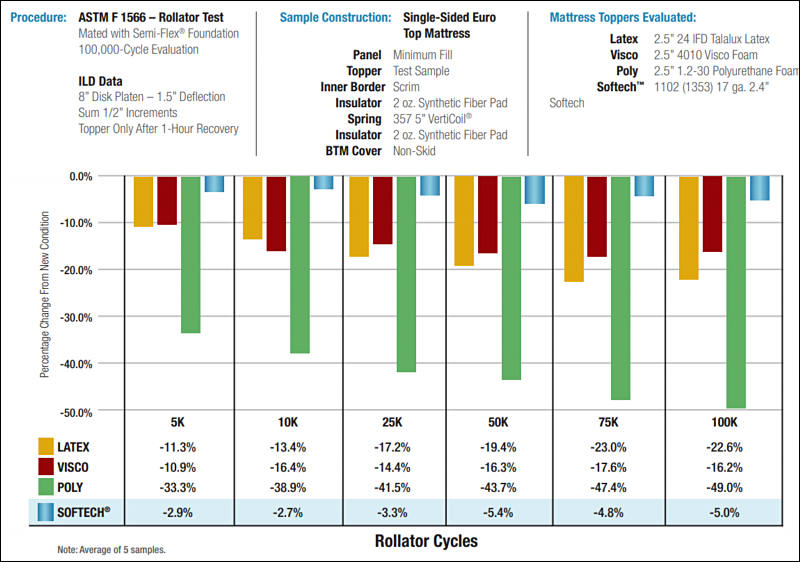

One of these as you mentioned ... and the one that is the most commonly talked about is ILD (or IFD which is very similar and is used more with polyfoam). ILD means Indentation load deflection while IFD means indentation force deflection. IFD is done with a small pre-weight to very slightly compress the surface before the testing weight is applied but they are functionally the same (assuming the same layer thickness and percentage compression is being tested). The PFA has some good information about IFD and several of the other factors in this post.

It's "standard definition" is the amount of weight that it takes to compress a 4" thick layer, 20" x 20", 25% of its thickness using a 50 sq inch circular metal press or "foot". Once a foam is rated ... then thinner "cuts" of this foam from the rated slab are still rated at the same IFD. So if a "slab" of polyfoam or other material is rated at a certain IFD (using a 4" piece) then all thicknesses that are cut from this slab are rated at 24 IFD. If a 6" layer of latex for example is rated at a certain ILD ... then six 1" toppers that are cut from it would all be rated at the same ILD.

This gets confused though because different materials and different areas of the world use different methods of measurement. Some latex (like talalay which is produced in 6" cores) for example measures IFD @ 25% with a 6" slab (which would then be rated higher than a 4" piece) while some areas of the world use IFD @ 40% compression instead of 25% which also results in a firmer rating. Other areas or materials ( such as latex green ) use kgf (kilograms of force) which "looks like" much softer latex than a standard IFD test would produce (notice how low the numbers are). Sites all over the internet have simply posted the kgf rating except they call it ILD which is quite misleading as to how soft/firm it really is so some people that are using Latex Green layers for example believe that they will be softer than they really are and may have great difficulty getting their layering right. Because of the variations ... it is sometimes difficult to "translate" the softness or ILD of materials from one measurement to another unless the differences are taken into account or known through experience.

But the differences are only part of the story. Because standard IFD is measured at a 25% compression ... it is only really accurate if the mattress layer is compressed exactly that amount. In real life a layer is compressed either less or more than 25% (and different parts of the body have different weights as well which compress a mattress to different depths) so it may "feel" either softer or firmer depending on body weight and depth of compression. How much a layer compresses is of course also affected by where in the mattress the layer is and the "relative" ILD's of the layers because different materials or even the same type of material from different manufacturers may not be easily comparable based on ILD alone.

This brings us to the second critical part of what creates the "feel", "softness/comfort", and supportive qualities of different materials ... and this is called compression modulus. It is also called sag factor or support factor. This measurement takes the IFD at a 25% compression and a second IFD measurement at a 65% compression and the ratio between them is the compression modulus. Some foams like polyfoam typically have a lower compression modulus which means they don't get as firm with deeper compression and so will feel softer and bottom out more easily than those with a higher compression modulus. This measurement ... even though it is rarely discussed anywhere (at least on north american sites with the exception of the PFA site again) ... is just as critical a part of comfort and support as ILD and yet it is little realized or taken into account. Part of the reason that true HR (high resilience) polyfoam is a higher performance material compared to lower grade polyfoams is that by definition it must have a compression modulus of at least 2.4 (and a density of 2.5 as well) while lower grades of polyfoam have a compression modulus less than this (and often well below 2). Much of the polyfoam that is being sold as HR or high resilience foam isn't at all. Talalay latex is in the range of 3 while Dunlop is in the range of 4. This is why latex in general and Dunlop in particular can be soft on top and get firmer with increased compression and why single slab Dunlop layers were often used as a complete mattress. It could be both soft on top and supportive underneath in a single layer. The equivalent to compression modulus in an innerspring would be spring rate.

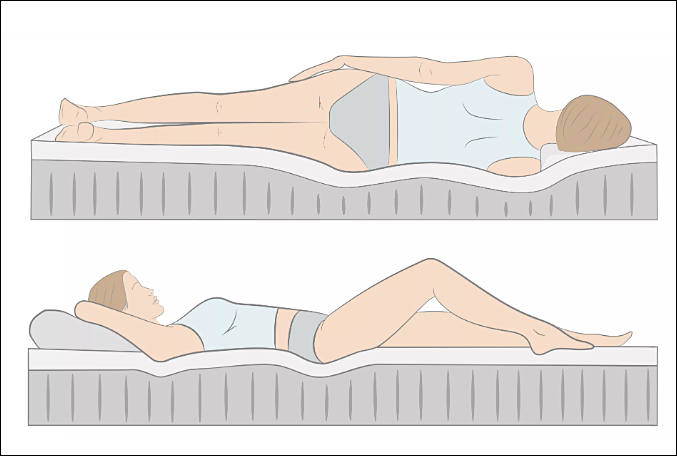

Third ... layer thickness plays a key role in how the comfort layers interact with the support layers and in tailoring a mattress to different body weights, body shapes, and sleeping positions. This site includes a fair bit of information about this and the 2 main layering schemes in this overview and the subsections about progressive construction and differential construction .

The fourth of the important specs that determine why some materials perform or feel differently than others is point elasticity which plays a key role in how well a material can "mirror" a body shape and relieve pressure (and why latex and memory foam are so good at this as they both have very good point elasticity). This is more applicable to comfort and transition layers than to support layers of a mattress. More information about this is in several parts of the site (you can search on point elasticity).

Fifth there is resilience (how strongly a material springs back) which is measured by how high a ball which is dropped on a material bounces (measured as a percentage of the height from which it is dropped) which can play a role in how well a material, especially in the comfort layers, supports the more recessed areas of the body, how easy it is to move on the mattress, and how much energy it absorbs vs returns. The "opposite" of resilience is hysteresis which is how much energy is absorbed by a material and not returned when the compression force is removed. Memory foam for example has high hysteresis and low resilience while latex has high resilience and low hysteresis.

Finally there is the effect of the sleeping environment because some types of material such as memory foam or gel memory foam are sensitive to temperature and humidity to different degrees and can change their softness based on different conditions in the bedroom.

While all the details about how these main "specs" of different materials and types of comfort and support layers can interact together are outside the scope of a single post (which would take many pages or even books) ... without a basic knowledge of how these factors interact ... it is very difficult to imagine or predict how a certain layering using certain materials may perform or "feel" for any specific individual. This is especially true if people only use ILD to make decisions without taking into account the major differences that the other factors can make in their choices. While this is rather technical to go into in each case ... these "specs" are mentioned in the glossary section of the site and discussed in more detail in various subsections of the "mattresses" section of the site for those who like to get more technical.

One of the reasons I am a "fan" of latex is because it can be made in a wide range of IFD's (ILD's) ... has the highest compression modulus of all foams ... has (along with memory foam) the best point elasticity of all the foams ... has the highest resilience of all the foams ... is the most breathable (coolest) of all the foams ... and has better durability than all other foams and most other mattress materials ... including steel innersprings.

Highly recommend posts by https://www.themattressunderground.com founder.

-

Some more latex manufacturing

-

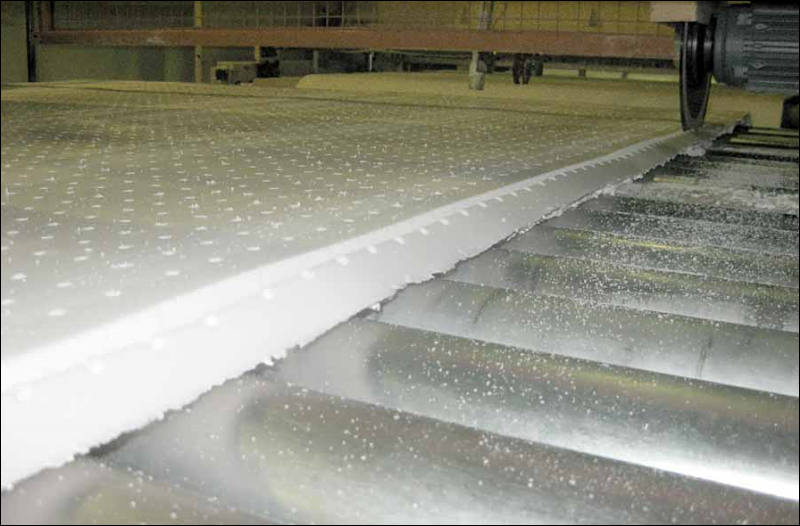

What happens to cheap foams in mattress?

And note that 35kg/m3 is not really very dense foam, good dense foams are 50-65kg/m3.

sa16466.jpg775 x 541 - 91K

sa16466.jpg775 x 541 - 91K -

In Australia the lowest density (weight) foam made is 15 kilograms per cubic metre and the average density of foam sold is around 19 kilograms per cubic metre. 30 years ago the average density sold was about 24 kilograms per cubic metre but as price is such an important issue in the Furniture Industry (because of competition internally and imports externally) many manufacturers are using more and more low quality foam.. This is a big pity – however a sign of the times.

Capitalism is extremely bad and inefficient thing.

In most applications as I said, 35kg/m3 minimum must be set and for mattresses it must be from 40kg/m3 up to 60kg/m3. This is real way to not produce lot of waste, contrary to idiotic claims of processing of degraded and used foam (very costly and you can do only limited thing from it, usually of low quality).

Howdy, Stranger!

It looks like you're new here. If you want to get involved, click one of these buttons!

Categories

- Topics List24,087

- Blog5,725

- General and News1,398

- Hacks and Patches1,153

- ↳ Top Settings33

- ↳ Beginners256

- ↳ Archives402

- ↳ Hacks News and Development56

- Cameras2,395

- ↳ Panasonic995

- ↳ Canon118

- ↳ Sony156

- ↳ Nikon96

- ↳ Pentax and Samsung70

- ↳ Olympus and Fujifilm102

- ↳ Compacts and Camcorders300

- ↳ Smartphones for video97

- ↳ Pro Video Cameras191

- ↳ BlackMagic and other raw cameras143

- Skill1,960

- ↳ Business and distribution66

- ↳ Preparation, scripts and legal38

- ↳ Art149

- ↳ Import, Convert, Exporting291

- ↳ Editors191

- ↳ Effects and stunts115

- ↳ Color grading197

- ↳ Sound and Music280

- ↳ Lighting96

- ↳ Software and storage tips266

- Gear5,420

- ↳ Filters, Adapters, Matte boxes344

- ↳ Lenses1,582

- ↳ Follow focus and gears93

- ↳ Sound499

- ↳ Lighting gear314

- ↳ Camera movement230

- ↳ Gimbals and copters302

- ↳ Rigs and related stuff273

- ↳ Power solutions83

- ↳ Monitors and viewfinders340

- ↳ Tripods and fluid heads139

- ↳ Storage286

- ↳ Computers and studio gear560

- ↳ VR and 3D248

- Showcase1,859

- Marketplace2,834

- Offtopic1,343