It allows to keep PV going, with more focus towards AI, but keeping be one of the few truly independent places.

-

The Dutch company ASML reported its work in the second quarter of calendar 2021. The world's only manufacturer of advanced lithographic scanners for the production of chips sees a sharp and steady increase in demand for its products.

The speculations and total monopoly helped ASML increase its quarterly revenue and bottom line. Orders for lithographic equipment rose 75% quarter-on-quarter to 8.3 billion euros ($ 9.78 billion), and the company's net profit rose 38% to 1 billion euros ($ 1.17 billion).

ASML is now becoming biggest hurdle on he road of progress.

-

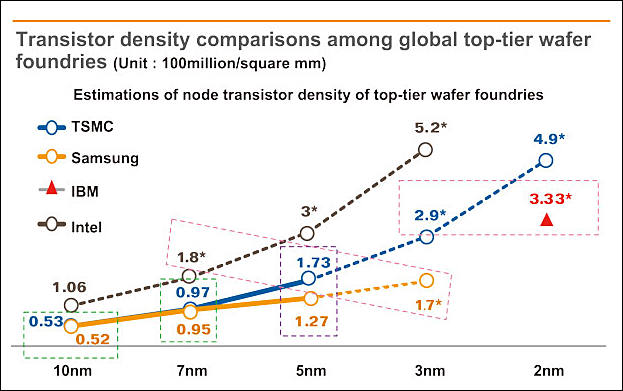

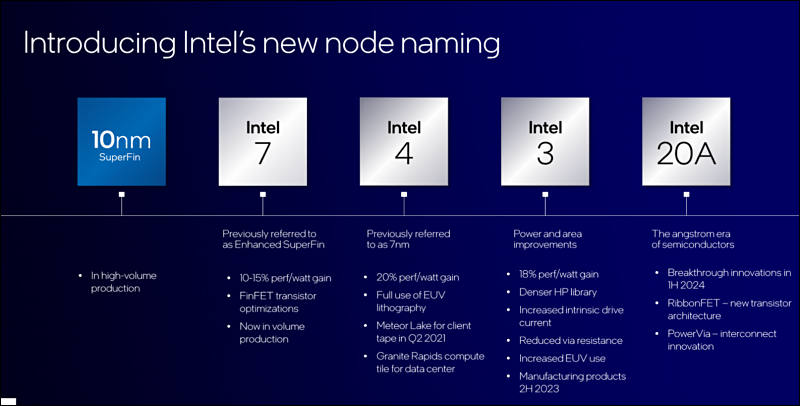

Intel officially declared that it is now marketing that reduces "nanometers"

Future Intel products (from 12th Gen Alder Lake) will no longer use the nanometer-based node nomenclature that both it and the rest of the chipmaking industry has used for years.

Intel is debuting a new naming scheme that it says will provide “a more accurate view of process nodes across the industry” and how Intel’s products fit into that landscape.

Third-generation 10nm chips will be referred to as “Intel 7,” instead of getting some 10nm-based name.

- Intel 7 (formerly Intel 10nm Enhanced SuperFIN technology) - will provide an increase in performance per watt of about 10-15% compared to Intel 10nm SuperFin by optimizing the structure of FinFET transistors. The technology will be used in the production of Alder Lake processors due this year and Sapphire Rapids server chips, which will begin shipping in the first quarter of 2022.

- Intel 4 (formerly Intel 7nm) - Will provide about 20% improvement in performance per watt along with further increases in transistor density and the introduction of EUV lithography. Intel 4 will debut in the second half of 2022 and will be used in Meteor Lake client processors and Granite Rapids server processors due in 2023.

- Intel 3 - Delivers about 18% performance per watt gain over Intel 4, leveraging further FinFET optimizations and enhanced EUV lithography. Intel 3 is expected to be ready for mass production in the second half of 2023.

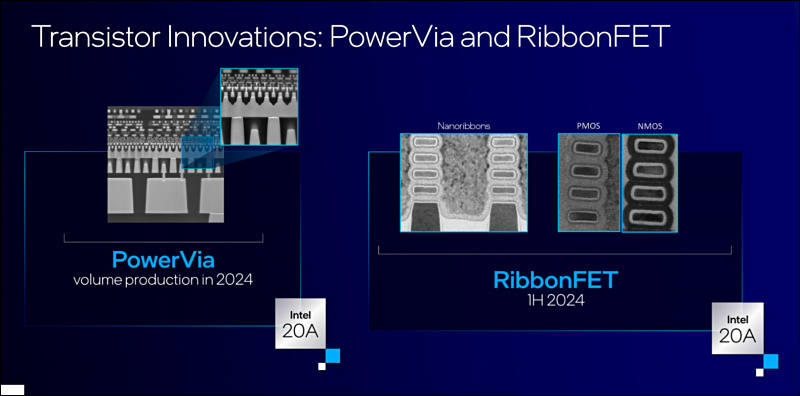

- Intel 20A - will be the first Intel process technology with the dimension of transistors in angstroms. The Intel 20A is expected to launch in 2024.

- Intel 18A - slated for early 2025. At this stage, Intel intends to implement High NA EUV lithography, for which the company is partnering with ASML.

sa17826.jpg800 x 406 - 43K

sa17826.jpg800 x 406 - 43K

sa17827.jpg800 x 396 - 42K

sa17827.jpg800 x 396 - 42K -

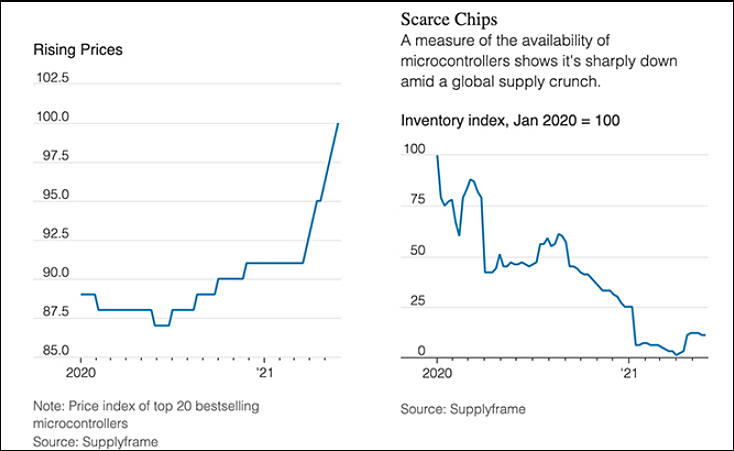

United Microelectronics (UMC) plans to raise its foundry quotes for 40nm process technology by 10-15% starting the first quarter of 2022, as well as quotes for other mature process nodes by 5-10%, according to sources at IC design houses.

Inflation is picking up fast.

-

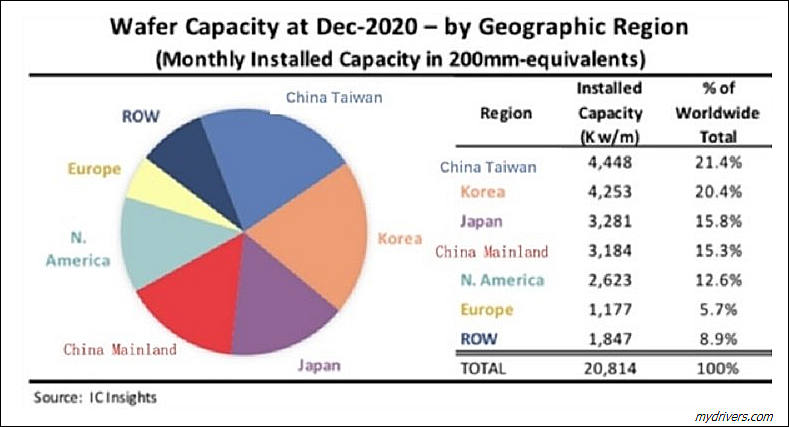

The planned TSMC fab in Kumamoto, on the island of Kyushu in western Japan, would go forward in two phases, according to Nikkei Asia. The board of TSMC is expected to decide on the investment in the current quarter.

The plant is expected to start operation in 2023. Once both phases are complete, the new fab will produce about 40,000 wafers per month in 28nm process. The fab is expected to be mainly used to make image sensors for Sony, TSMC's largest Japanese customer. Nikkei has been told that TSMC is open to a collaboration that would give Sony more say in operating the plant and negotiating with the Japanese government.

sa17777.jpg800 x 586 - 76K

sa17777.jpg800 x 586 - 76K -

Globalfoundries (GF) has announced expansion plans for its most advanced manufacturing facility in upstate New York over the coming years. These plans include immediate investments to address the global chip shortage at its existing Fab 8 facility as well as construction of a new fab on the same campus that will double the site's capacity.

GF said it will invest US$1 billion to immediately add an additional 150,000 wafers per year within its existing fab to help address the global chip shortage.

Big price hikes had been required for this.

Company also is getting ready for merger with Intel.

-

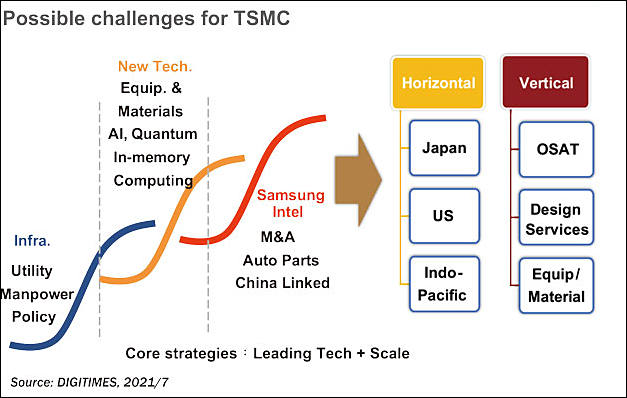

Biggest challenge for TSMC is understanding its true role.

As it is designed to be biggest lure for China to try to force Chinese elites it to escalate Taiwan conflict.

This is why US directly poured tens of billions of dollars for very long time into company, and this is why they ordered their largest corporations to move production to TSMC, even at the times where it was doubtful thing to do.

sa17685.jpg627 x 398 - 47K

sa17685.jpg627 x 398 - 47K -

TSMC is gearing up for a bigger presence in the automotive IC foundry market segment, with its newly-developed N5A process set to be available in the third quarter of 2022, according to industry sources.

TSMS PR expenses are now highest ever, and soon you will be watching how for hundreds of millions of marketing TSMC will be selling you old 7nm as newest 4nm process.

-

Intel is currently considering Germany, the Netherlands, France, Italy and Belgium as possible sites for the construction of a new enterprise. The main requirement, in addition to the availability of a free plot of land with an area of 405 hectares, is the availability of the necessary engineering infrastructure and access to qualified labor. Starting with two factories, Intel could eventually expand to eight, with an initial budget of $20 billion over the next decade could grow to $100 billion.

Intel is now trying to figure out exactly what local customers are interested in. The management of the processor giant believes that it will be difficult for Europeans to compete with Asian manufacturers without government subsidies, but the costs can be borne together, dividing them not only between large companies, but also between states. By joint efforts, it is possible to carry out not only development and research, but also the manufacture of the final product. Silicon wafers can be processed in one country and become ready-to-use chips in another. Now this is happening, it is just that the indicated links of the technological chain are better placed in Europe, according to Intel representatives.

It is now same for all of them, as they try to steal lot of taxpayers money.

-

Taiwan as part of criminal plot

Revenue from the export of integrated circuits and semiconductor stuff in June reached a record high. China and the United States remained the most loaded export destinations, demonstrating an increase in profile revenues by 37.8 and 34.5% compared to the previous year's level, respectively.

Total exports revenue of Taiwan across all industries in June grew by 35.1% year-on-year to $ 36.7 billion, which is already the second highest value on record. Import revenue increased by 42.3% to $ 31.5 billion, the foreign trade balance increased to $ 5.2 billion compared to last year.

All we saw is planned crime that involved mass media and top leading corporations and banks.

-

Secret of auto chip shortages revealed

IC foundries including TSMC, United Microelectronics (UMC) and Vanguard International Semiconductor (VIS) have signed supply contracts with their automotive customers for orders set to be fulfilled in 2022 and 2023.

Manufacturers will pay big money in advance. As IC guys need lot of money, tens of billions now.

-

Nikkei Asian Review cites recent comments from Huawei CEO Catherine Chen. The Chinese giant is determined to continue developing semiconductor components in-house, she said, and the HiSilicon division will not undergo any restructuring or downsizing. In 2020, the number of HiSilicon employees exceeded 7000 people.

This is interesting.

-

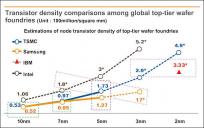

At the beginning of 2019, Samsung Electronics hoped to implement a 3nm process technology in the 3GAE variety by the end of 2020 at the pilot production stage, and by the end of 2021, move to mass production. Compared to 7nm technology, the plan was to increase the switching speed of transistors by 35%, reduce power consumption by 50%, and the density of the transistors was to increase by 45%. The targets are currently revised downward. For example, the gain in speed has been reduced to 10%, the increase in density has been reduced to 25%, and in terms of energy consumption, progress has deteriorated to 20%. Informed sources report that the appearance of 3-nm serial products in the performance of Samsung will have to wait until 2024.

Its the wall.

-

The existing shortage of chips in the electronics market will continue to worsen and will peak in the second half of this year, said Intel CEO Pat Gelsinger. He told about this in an interview with Bloomberg.

“I don't think the chip industry will return to a healthy balance of supply and demand by 2023, I think things will get worse in a wide variety of industries before they get better."

-

TSMC alone accounts for 92 percent of the supply of cutting-edge chips, with Samsung providing the rest. The company also reportedly makes about 60 percent of the chips for car manufacturers around the world. Which means that when those companies run out of capacity, there’s not a lot of other places to go to get those processors.

Imperialism, the last stage of capitalism.

Demise era.

-

Sales of smartphones in the China market remained lackluster in May, with related shipments declining 31% from a year earlier to 22.6 million units in the month, according to data from the China Academy of Information and Technology (CAICT).

As we can see shortage of chips is artificially made thing.

-

Taiwan-based IC design houses, including first-tier players and those specializing in LCD driver ICs and MOSFET chips, have been notified by their foundry partners about another price hikes starting July 1.

You will see the wall meetup in slow motion soon.

-

TSMC is set to move N4 (namely 4nm process) to risk production in the third quarter of 2021, while its N3 technology development is on track with volume production scheduled for second-half 2022.

Both so highly advertised processes want to keep same FinFET transistors and keep all the heavy logic areas on almost same size.

Also it is not clear how soon or if at all TSMC will propose full performance variants of tech.

TSMC 5nm still exist only as totally limited mobile only thing, where it is only Apple that special integrated chips that can use it.

-

No, they seriously need your money

A group of bipartisan lawmakers on the Senate Finance Committee have introduced legislation that seeks to incentivize chipmakers to manufacture their silicon in the US. The Facilitating American-Built Semiconductors Act would provide companies with a 25 percent tax credit when they invest in domestic semiconductor manufacturing equipment and facilities.

According to the panel, as much as 70 percent of the cost advantage overseas chip foundries offer come on the back of foreign subsidies. The proposed subsidy would be in addition to the $52 billion the Senate earmarked last week as part of the US Innovation and Competition Act.

Interesting facts, isn't it?

All over the world government criminals go into people pockets to make super profitable chip makers at the others expense to later just steal this money and live posh life.

-

Intel CEO Pat Gelsinger said that he expects 10 “good years” of growth in the semiconductor industry during a panel at CNBC’s Evolve conference on Wednesday.

“We believe the market, the world, is in a very expansionary period,” Gelsinger told CNBC’s Jon Fortt. “I predict there’s 10 good years in front of us, because the world is becoming more digital, and everything digital needs semiconductors.”

This is not some accident, as such guys start to talk about "10 good years" you need expect wall being hit at any moment now.

Only in past year this guys already scammed world for more than 100 billions, and I am not counting almost same amount they got free from taxpayers pockets.

-

Unstable shipments of Intel's recently introduced Tiger Lake-U Refresh processors, coupled with the ongoing shortages of certain ICs, will put pressure on the supply chain in releasing notebooks with the new processors in the third quarter of 2021, according to industry sources.

Intel also needs money.

Howdy, Stranger!

It looks like you're new here. If you want to get involved, click one of these buttons!

Categories

- Topics List23,992

- Blog5,725

- General and News1,354

- Hacks and Patches1,153

- ↳ Top Settings33

- ↳ Beginners256

- ↳ Archives402

- ↳ Hacks News and Development56

- Cameras2,367

- ↳ Panasonic995

- ↳ Canon118

- ↳ Sony156

- ↳ Nikon96

- ↳ Pentax and Samsung70

- ↳ Olympus and Fujifilm101

- ↳ Compacts and Camcorders300

- ↳ Smartphones for video97

- ↳ Pro Video Cameras191

- ↳ BlackMagic and other raw cameras116

- Skill1,960

- ↳ Business and distribution66

- ↳ Preparation, scripts and legal38

- ↳ Art149

- ↳ Import, Convert, Exporting291

- ↳ Editors191

- ↳ Effects and stunts115

- ↳ Color grading197

- ↳ Sound and Music280

- ↳ Lighting96

- ↳ Software and storage tips266

- Gear5,420

- ↳ Filters, Adapters, Matte boxes344

- ↳ Lenses1,582

- ↳ Follow focus and gears93

- ↳ Sound499

- ↳ Lighting gear314

- ↳ Camera movement230

- ↳ Gimbals and copters302

- ↳ Rigs and related stuff273

- ↳ Power solutions83

- ↳ Monitors and viewfinders340

- ↳ Tripods and fluid heads139

- ↳ Storage286

- ↳ Computers and studio gear560

- ↳ VR and 3D248

- Showcase1,859

- Marketplace2,834

- Offtopic1,320